扫码关注

-

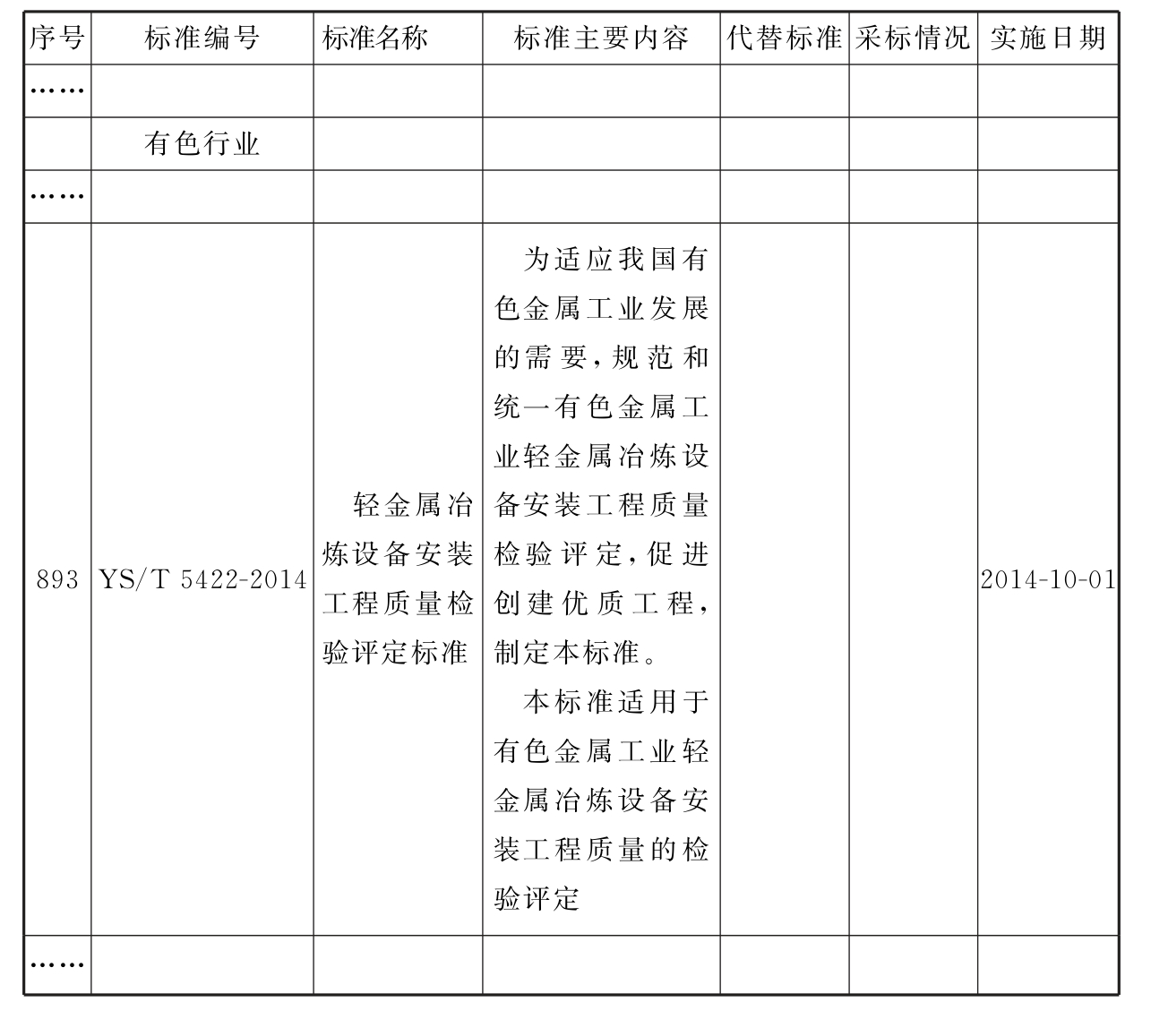

【主编部门】

中国有色金属工业协会

-

【批准部门】

中华人民共和国工业和信息化部

-

【发布单位】

中华人民共和国工业和信息化部

-

【主编单位】

有色金属工业建设工程质量监督总站九冶建设有限公司

-

【参编单位】

有色金属工业建设工程质量监督总站长城铝监督站;有色金属工业建设工程质量监督总站青铜峡监督站;有色金属工业建设工程质量监督总站山西铝监督站;有色金属工业建设工程质量监督总站平果铝监督站;有色金属工业建设工程质量监督总站中州铝监督站;有色金属工业建设工程质量监督总站贵州铝监督站;有色金属工业建设工程质量监督总站青海铝监督站;有色金属工业建设工程质量监督总站焦作万方监督站;有色金属工业建设工程质量监督总站中孚监督站;中国有色金属工业第六冶金建设有限公司;七冶建设有限责任公司

-

【主要起草人】

贾明星;蔡胜利;王化林;王延伶;华新生;朱定金;黄升埙;李清富;吕 轩;张金娥;余凤红;郭红永;任晓妮;胡建平;李玉保;黄遂新;李 冰;刘 涛;石立刚;何学宁;徐 旋;李 波;柴世伟;董 峰;田柯昌;王强(平果);王强(中州);王联峰;陈晓山;龙 林;王应刚;马成俊;王国勤;崔英伟;刘公道;张海龙;孙方抒

-

【主要审查人】

何忠茂;刘 兵;李俊峰;张荣京;张建国;李荣健;邹利广;张劲松;姜汉杰;张志强;陈建平;江 嵩;李 汇;章仕军

知识服务平台

知识服务平台

纸书购买

纸书购买

京公网安备 11010202009407号

京公网安备 11010202009407号